Complete Engineering Solutions

Improved technologies for manufacturing our products

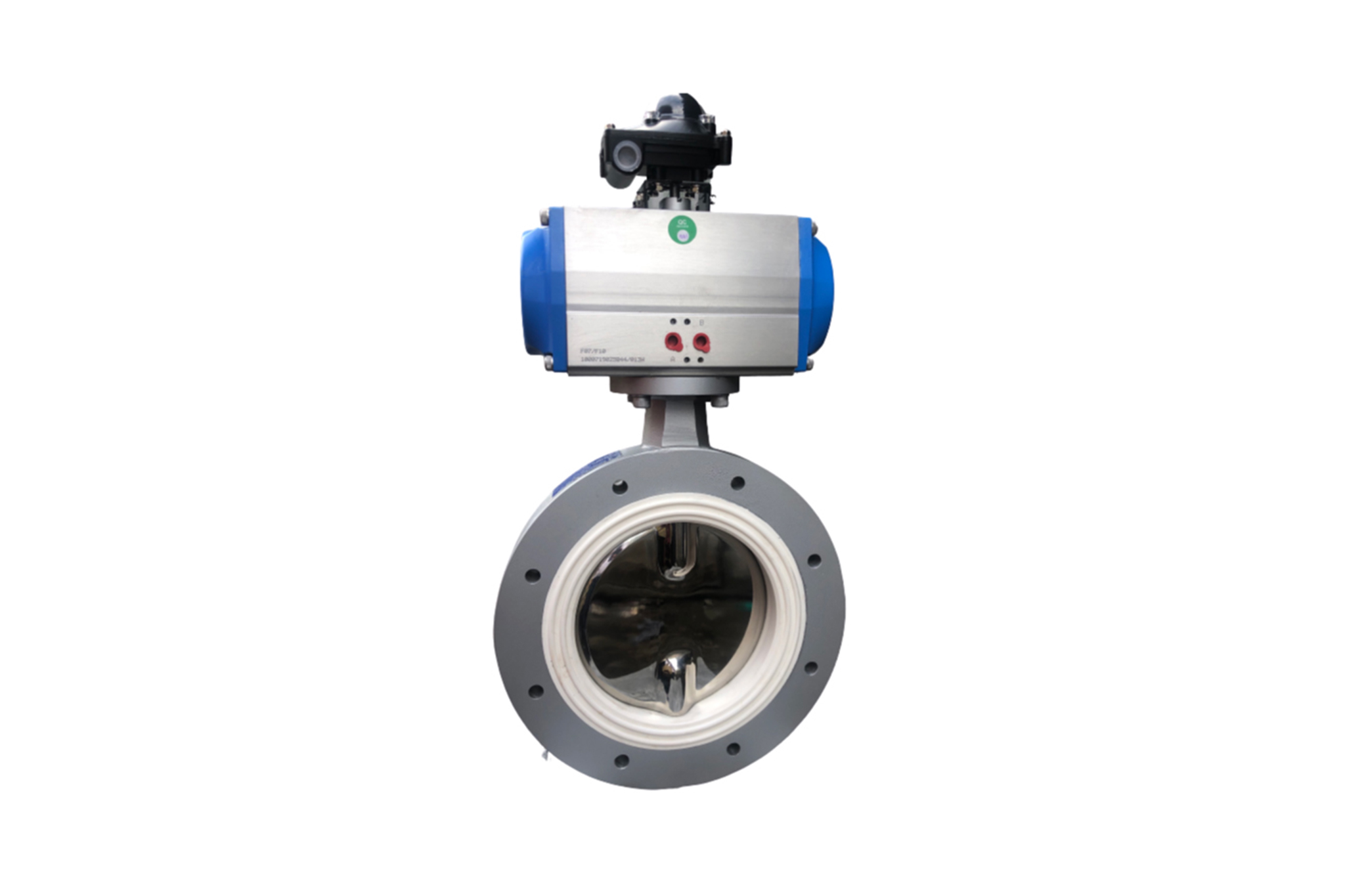

Mehtech Engineering Pvt. Ltd. specializes in the production of high performance butterfly valves, offering different variants. Founded in the year 1987, our Company is registered with ISO 9001:2008 certificate in respect of the general engineering services. All our products adhere to strict quality standards and we do ensure that each valve manufactured precisely meets the requirements of the specific applications of our customers. At Mehtech Engineering, understand that unique needs require unique solutions. We offer customization options to ensure our valves seamlessly integrate into your existing systems and meet your specific performance criteria. we strive for exceptional pre-sale and after-sale services. We are able to achieve our objectives due to our skilled team which has experts in respective fields and timely delivery of the requirements of our valuable clients.

Butterfly Valve Exporter Company in Middle East: We supply Butterfly Valves to pharma industries with Aluminium body And stainless steel body from sizes Dn 100 to Dn 600 with pressure rating upto 10 Bar, with decades of experience in manufacturing butterfly valves to many the leading pharma companies ,mehtech understands your need perfectly (Butterfly Valve Exporter Company in America).

Product introduction:

Butterfly valves are widely used in various industries including the pharmaceutical sector, for controlling the flow of fluids. These valves are particularly favored for their compact design, ease of operation and cost effectiveness. In the pharmaceutical industry, where precision and hygiene are paramount, butterfly valves play a crucial role in maintaining the integrity of processes.

Features:

1. Material Selection: Butterfly valves used in pharmaceutical industries

are typically made from high quality materials such as stainless steel or other corrosion resistant alloys. This ensures that the valves meet stringent hygiene standards and can resist the adverse conditions of

pharmaceutical processes.

2. Sanitary Design: The design of butterfly valves for the pharmaceutical sector often incorporates sanitary features such as smooth, gap free surfaces to prevent the accumulation of contaminants. This is crucial to

maintain the purity of pharmaceutical products.

3. Sterilization: Butterfly valves in these type of industries must be designed to handle sterilization procedures such as clean in-place systems. This ensures the elimination of micro organisms and

contaminants from the valve surfaces.

4. Precision Control: Butterfly valves offer precise control over the flow

of fluids, making them suitable for applications where precise control is

essential.

5. Quick Opening and Closing: The quick and efficient operation of

butterfly valves is beneficial in pharmaceutical procedures where rapid

response and control are required.

6. Easy Maintenance: Butterfly valves are often designed for easy

disassembly and cleaning, facilitating routine maintenance and

minimizing downtime.

7. Validation Protocols: Pharmaceutical industries adhere to strict

validation protocols and butterfly valves need to comply with these

standards to ensure reliability and consistency in processes.

8. Unmatched Performance: Our valves deliver exceptional flow control,

minimal pressure loss, and reliable operation, even in demanding

applications.

Types of Butterfly Valves used in pharmaceutical process:

1. High Performance Butterfly Valves: These valves are designed for

applications where tight shut off is critical, providing a reliable seal even

in high pressure or high temperature conditions.

2. Sanitary Butterfly Valves: Specifically designed for hygienic

applications, these valves are easy to clean and maintain, meeting the

stringent requirements of the pharmaceutical industry.

Applications in Pharmaceutical Processes:

1.Material Transfer: Butterfly valves are used in pharmaceutical

manufacturing processes for the transfer of raw materials, intermediates

and finished products.

2.Batch Processing: They find application in batch processing, where

precise control of fluid flow is essential for maintaining product quality.

3.Cleanroom Environments: Butterfly valves are suitable for use in

cleanroom environments due to their sanitary design and ease of

maintenance.

We are dedicated to exceeding your expectations through continuous improvement, innovation and exceptional customer service. Partner with Mehatech Engineering and experience the peace of mind that comes with utilizing high-performance butterfly valves you can trust.

Contact us today to discuss your specific requirements and receive a quote.

- Highly skilled professionals who have great knowledge on this domain

- Very well aware of the standards and norms of the Industry

- Improved technologies for manufacturing our products

- Timely delivery of the same